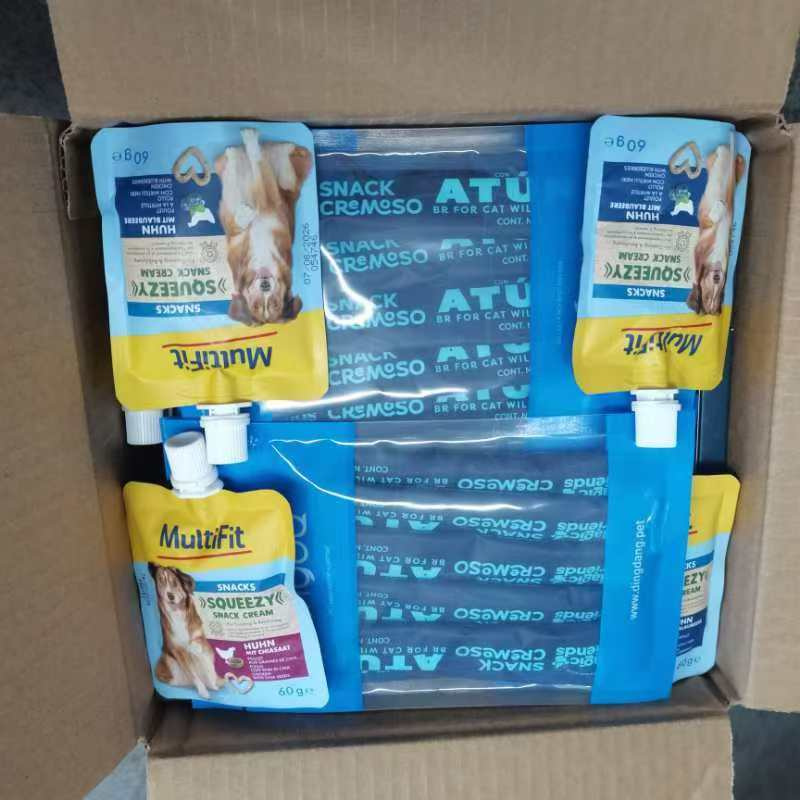

In Recent Years, With The Continuous Growth Of The Pet Market, Competition In The Pet Food Industry Has Become Increasingly Fierce. In This Market Centered On Health And Quality, Shandong Dingdang Pet Food Co., Ltd., As a High-Quality Pet Snack Supplier, Has Once Again Won The Favor Of The Market By Constantly Exploring Innovation And Relying On Its Excellent Production Capacity And R&D Strength, And Successfully Obtained An Order Of 600 Tons Of Liquid Cat Snacks. The Achievement Of This Major Order Not Only Demonstrates The Company's Leading Position In The Field Of Liquid Cat Snacks, But Also Promotes The Upgrading Of The Production Scale And Technology Of The Entire Factory.

New Workshops And Equipment Upgrades Lead The Development Of The Industry

Liquid Cat Snacks Have Gradually Become a Superior Product In The Pet Food Market Due To Their Convenience And Easy Digestibility. The Reason Behind This 600-Ton Order Is The Company's Accurate Grasp Of Market Trends And Its Continuous Innovation And Quality Assurance In Production Processes. As a Professional Factory For Oem Cat Treats, The Company Has Always Been Customer-Oriented And Committed To Providing High-Quality And Healthy Products To Global Pet Food Brands.

In Order To Successfully Complete This 600-Ton Order And Further Improve Production Capacity, Shandong Dingdang Pet Food Co., Ltd. Specially Introduced 8 New Liquid Cat Snack Production Machines. These Latest And Most Advanced Production Machines Can Carry Out Large-Scale Production Operations More Efficiently And Stably, Which Can Not Only Shorten The Production Cycle, But Also Increase Production While Ensuring Product Quality, And Meet Customers' Demand For Large-Volume Orders.

At The Same Time, These Machines Are Also An Important Step For The Factory In Automation And Intelligence. Through The Precise Control Of The Automated Assembly Line, It Not Only Reduces The Error Of Manual Intervention, But Also Improves The Uniformity And Consistency Of The Product, Ensuring That Each Batch Of Liquid Cat Snacks Can Meet The High Standards Of Customers. In Addition, The Factory Also Realizes The Full Control Of The Production Process Through The Intelligent Monitoring System Of The Machine. From Raw Material Input To Finished Product Packaging, Every Link Is Under Strict Quality Control To Ensure The High-Quality Output Of The Product.

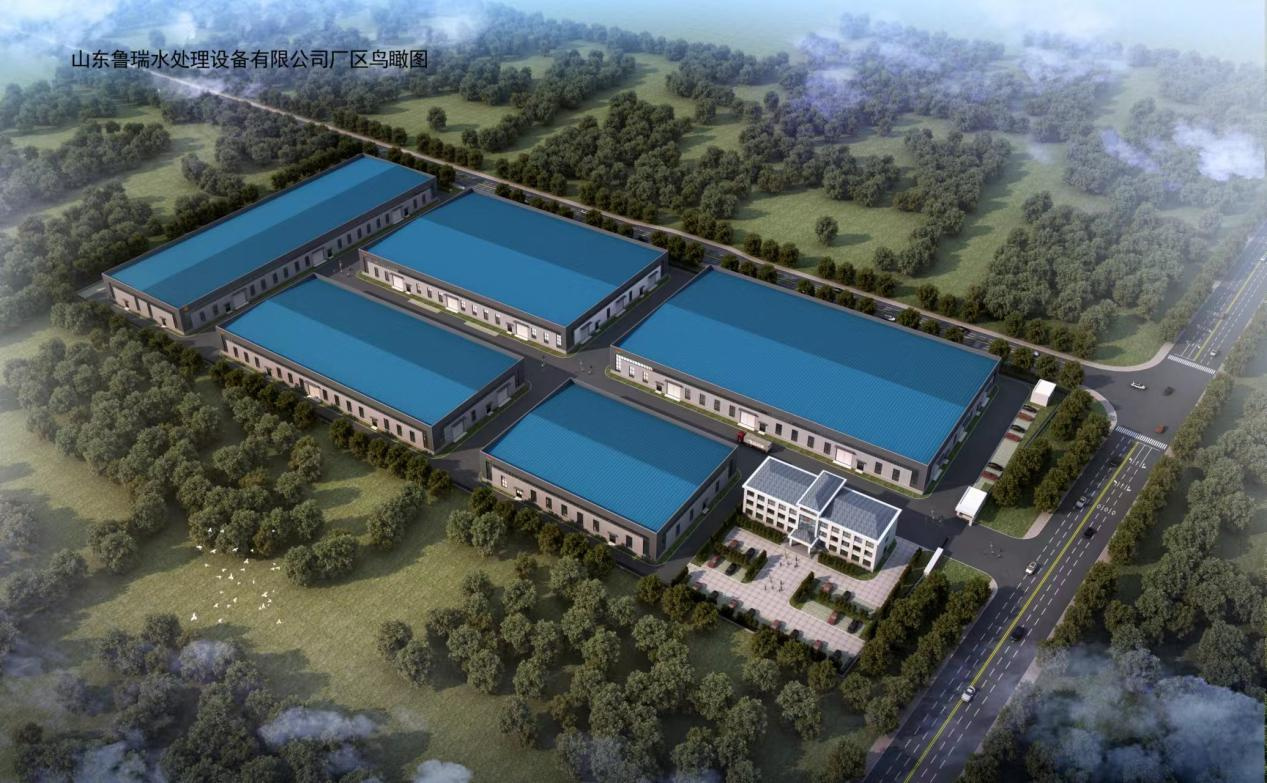

10,000-Meter New Workshop: Larger Layout, More Professional Service

In Addition To The Continued Growth Of Liquid Cat Snack Orders, Dog Snack Orders Have Also Increased By 50% Compared With Last Year. In Order To Cope With The Increase In Orders, The Company Invested Heavily In Building a New Production Workshop Of 10,000 Square Meters. This New Workshop Is Not Only Larger In Area, But Also More Advanced In Facilities. The New Workshop Is Rationally Planned, Clearly Divided, And Each Functional Area Is Independent But Closely Coordinated, Covering Multiple Links Such As Raw Material Storage, Production And Processing, Quality Inspection And Packaging, Forming a Complete Production Chain, Perfectly Matching The Increase In Production Capacity

The Expansion Of The Workshop Is Not Only To Cope With The Current Order Demand, But Also To Focus On Long-Term Development In The Future. The Construction Of The New Workshop Leaves Enough Space For The Future Expansion Of The Factory. Through This Strategic Investment, The Company Can Not Only Cope With More Market Orders, But Also Lay a Solid Foundation For Further Increasing Production Capacity And Optimizing Production Processes.

The Acquisition Of The 600-Ton Liquid Cat Snack Order, The Construction Of The New Workshop And The Introduction Of New Equipment Mark Another Leap Forward For The Company As An Oem Pet Snack Supplier In The Industry. In The Future Development Path, The Company Will Continue To Use Technological Innovation As The Driving Force, Continuously Optimize Production Processes, Improve Product Quality, And Strive To Inject More New Vitality And Innovation Into The Pet Industry.

Post time: Sep-30-2024